Menu

- Home

- Products

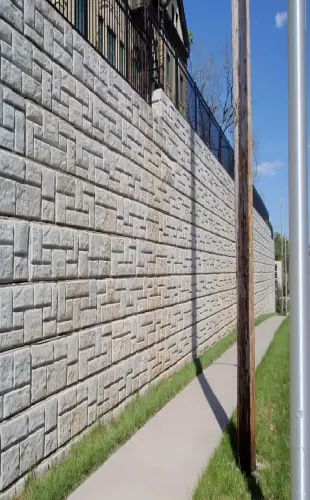

- Retaining Walls

- Seawalls

- Septic Tanks

- Septic Tank Lids

- Septic Tank Risers

- Distribution Box

- Lift Stations

- Grease Trap Tanks

- Concrete Parking Stops

- Infiltrator Products

- EZsnap Risers

- Septic Lids & Risers

- The Infiltrator IM-1530 Septic Tank

- The Infiltrator IM-1060 Septic Tank

- Infiltrator IM-540 Septic Tank

- Eco Filter Pump Vault

- Ecopod Commercial Advanced Wastewater Treatment Unit

- Enviro-Aire Advanced Wastewater Treatment Unit

- Ecopod-N Advanced Wastewater Treatment Unit

- Ecopod-NX Advanced Wastewater Treatment Units

- Spec-Check

- Enviro-Septic

- The Advanced Enviro-Septic

- Aquaworx Marc

- Aquaworx Remediator

- Aquaworx Intelligent Pump Control Panel

- Quick4 Equalizer 36 Chamber

- Quick4 High Capacity Chamber

- Quick4 Chamber Standard

- EzFlow

- About Us

- Reviews

- Blog

- FAQ

- Gallery

- Contact Us

- Home

- Products

- Retaining Walls

- Seawalls

- Septic Tanks

- Septic Tank Lids

- Septic Tank Risers

- Distribution Box

- Lift Stations

- Grease Trap Tanks

- Concrete Parking Stops

- Infiltrator Products

- EZsnap Risers

- Septic Lids & Risers

- The Infiltrator IM-1530 Septic Tank

- The Infiltrator IM-1060 Septic Tank

- Infiltrator IM-540 Septic Tank

- Eco Filter Pump Vault

- Ecopod Commercial Advanced Wastewater Treatment Unit

- Enviro-Aire Advanced Wastewater Treatment Unit

- Ecopod-N Advanced Wastewater Treatment Unit

- Ecopod-NX Advanced Wastewater Treatment Units

- Spec-Check

- Enviro-Septic

- The Advanced Enviro-Septic

- Aquaworx Marc

- Aquaworx Remediator

- Aquaworx Intelligent Pump Control Panel

- Quick4 Equalizer 36 Chamber

- Quick4 High Capacity Chamber

- Quick4 Chamber Standard

- EzFlow

- Retaining Walls

- About Us

- Reviews

- FAQ

- Gallery

- Contact Us