Here at Garrett Precast, we always keep tabs on what’s going on in the construction industry, so we are familiar with the challenges and opportunities that arise. As a leading supplier of precast concrete products, we are committed to solving these challenges by offering high-quality products.

Tight Timelines and Delays

Construction projects are often under immense pressure to meet deadlines. Everything from inclement weather to material shortages and labor issues can all contribute to costly delays. The use of traditional materials like poured-in-place concrete exacerbates these issues because it’s highly dependent on favorable weather conditions and on-site labor availability. Conversely, precast concrete products offer a significant advantage in this regard. Precast concrete components are manufactured off-site in controlled environments, thereby eliminating weather-related delays.

The prefabrication process ensures faster assembly and reduces project timelines. Contractors who need to adhere to tight schedules find precast concrete an invaluable asset. Apart from helping contractors achieve greater predictability, precast concrete can mitigate the costly consequences of unforeseen delays.

Labor Shortages

Finding and retaining skilled labor is a persistent challenge in the construction industry. This can be attributed to several factors, including an aging workforce and a skills gap resulting from evolving technologies. Precast concrete requires less on-site labor compared to traditional methods. Factory fabrication streamlines the process, thereby reducing the reliance on large crews. Contractors who’ve opted for precast concrete products have found an advantage in mitigating these labor challenges.

Cost Overruns

One of the challenges associated with poured-in-place concrete and other traditional materials is cost overruns. Unforeseen expenses, material price fluctuations, and project delays can increase the cost of a project and strain budgets. Luckily, precast concrete offers a more predictable and controlled cost structure. The components are manufactured in a factory setting, and material waste is minimized. Moreover, production schedules are optimized, thereby reducing the risk of unexpected expenses. Precast manufacturing provides greater cost predictability. Reduced on-site labor and faster construction times contribute to overall cost savings.

Quality Control

Ensuring consistent quality on-site can be difficult, especially with varying weather conditions and labor skills. The good thing about your precast concrete is that it’s manufactured in controlled factory settings to ensure consistent quality. Strict quality control measures are implemented during the manufacturing process. As long as you work with a professional precast company, you can be assured that each component meets stringent specifications. This controlled environment eliminates the variables that often compromise on-site poured concrete, such as temperature fluctuations, humidity, and varying labor expertise.

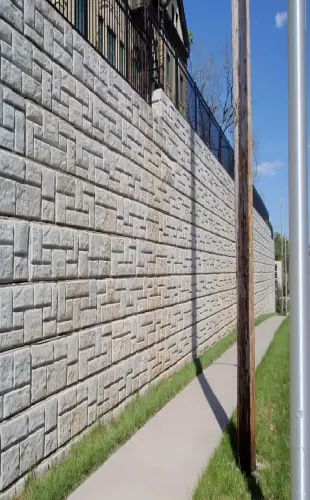

Precast concrete is undeniably a game changer in the construction industry, as it offers several advantages like speed, cost-effectiveness, and efficiency. It’s a sustainable and versatile choice for various projects, including tunnels, bridges, residential buildings, parking facilities, commercial structures, and many more.

Looking For a Trusted Precast Company? Reach Out To Garrett Precast

We manufacture and supply quality precast concrete products, including retaining walls, concrete septic tanks, seawalls, septic tank risers, and more. Our products are manufactured to the highest standards to ensure they stand the test of time. Contact us for more information about our precast products and place your order.