This article, brought to you by Garrett Precast, highlights the top seven reasons why precast concrete is a superior choice when compared to traditional construction methods. We are a reputable precast company providing a wide range of products, including seawalls, retaining walls, septic tank lids, septic tanks, and more.

Superior Quality Control

Precast concrete is manufactured in a controlled environment where quality checks are performed at every stage of production. Unlike traditional construction, where things like weather, inconsistent materials, or human error can affect quality, precast ensures uniformity and consistency. The use of standardized molds, high-quality materials, and advanced curing techniques results in stronger and more reliable structures.

Accelerated Construction Speed

Time is an important factor in construction projects, and precast concrete reduces build time compared to traditional methods. The installation process is quick since components are manufactured off-site and delivered ready for assembly. This eliminates long curing times and delays caused by unpredictable weather conditions. While traditional builds require sequential steps, precast allows for simultaneous site preparation and component fabrication.

Cost-Effectiveness

Precast concrete is known to reduce labor, construction time, and material waste. Therefore, it offers a more cost-effective solution than traditional construction methods. Production costs are lower because components are made in bulk under optimized conditions. Also, faster installation reduces expenses associated with extended labor and site management.

Enhanced Durability and Strength

One of the biggest advantages of precast concrete is its superior strength and durability. Unlike traditional concrete, which can be susceptible to inconsistencies during on-site pouring and curing, precast undergoes a controlled curing process that enhances its structural integrity. It is designed to withstand harsh weather, heavy loads, and environmental wear. This is one of the reasons it is an ideal choice for bridges, parking structures, and high-rise buildings. As long as you source your precast concrete from a professional precast company, you’ll be good to go.

Design Flexibility

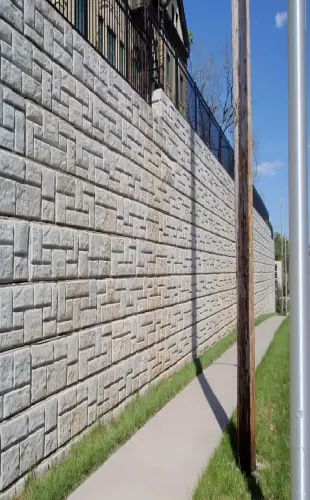

Many assume precast concrete limits design possibilities, but in reality, it offers incredible flexibility. With custom molds, architectural finishes, and various shapes and sizes available, it can be customized to fit a wide range of aesthetic and functional requirements. Whether it’s intricate façade details, unique textures, or curved structures, precast allows architects and engineers to push creative boundaries while maintaining structural efficiency.

Reduced On-Site Labor

Construction sites require skilled labor, but with labor shortages becoming more common, precast concrete provides a practical solution. Fewer workers are needed on-site for assembly since most of the work is done in a factory setting. This not only lowers labor costs but also minimizes safety risks associated with traditional on-site concrete pouring. Besides, projects in remote areas or regions with high labor costs benefit from the simplified installation process.

Minimized Material Waste

Traditional construction methods are not just inefficient, but the amount of material that goes to waste is unimaginable. Excessive material goes to waste due to inefficient on-site mixing, inaccurate estimations, and leftover materials. In contrast, precast concrete manufacturing optimizes resource use. Unnecessary material consumption is avoided since molds are reused and accurate calculations guide production. Furthermore, any unused concrete can be repurposed. It is safe to say that precast concrete products are a more sustainable and eco-friendly construction choice.

Contact Garrett Precast for quality precast concrete products that are manufactured to the highest standards.