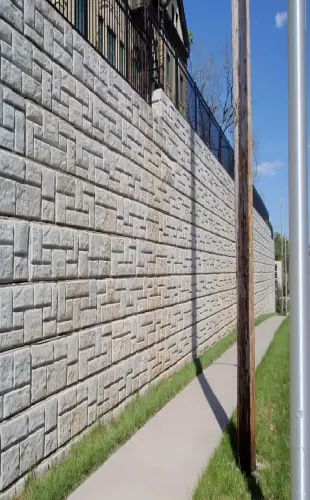

Here at Garrett Precast, we provide quality concrete precast products, including retaining walls, seawalls, septic tanks, and more. Our products are manufactured under strict quality control standards to ensure consistent strength and durability. Let’s walk you through the key aspects of designing a data center with precast concrete.

Introduction to Precast Concrete in Data Centers

Data centers are the backbone of our digital world, so they demand robust construction that can withstand the test of time and support sensitive equipment. Traditional construction methods can be slow and expensive, which is why precast concrete is gaining traction in data center design. This ground-breaking approach utilizes concrete components manufactured off-site in a controlled environment, then transported and assembled on location. This not only streamlines the construction process but also offers many other advantages. Precast concrete provides a persuasive solution for data center developers seeking speed, durability, and cost-effectiveness.

Structural Strength and Durability of Precast Concrete

When it comes to data centers, structural integrity is non-negotiable. Precast concrete shines in this area, offering exceptional strength and durability. The controlled manufacturing process ensures consistent quality and allows for precise control over the concrete mix. This results in components that are highly resistant to cracking, weathering, and even fire – critical considerations for protecting valuable data and equipment. Furthermore, precast concrete can be engineered to meet specific load requirements. Its resilience provides a long-lasting and reliable structure. You can rest assured knowing your data center is built on a solid foundation.

How Precast Concrete Speeds Up Construction

Speed is an important factor in data center construction, as businesses often need to bring new facilities online as quickly as possible. Precast concrete accelerates the building process by allowing various components to be manufactured simultaneously while site preparation takes place. This parallel workflow eliminates delays caused by unpredictable weather conditions and site-based constraints. Once the precast elements are ready, they can be transported and assembled rapidly. Moreover, since precast components are designed for precision, on-site modifications are minimized. If you work with a dependable precast company, you can expedite project completion without compromising on quality.

Does Precast Concrete Offer Any Environmental Benefits?

Sustainability is becoming a key consideration in data center design, and precast concrete offers several environmental advantages. Because it is produced in a controlled setting, material waste is reduced. Also, the thermal mass properties of precast concrete help regulate indoor temperatures. This reduces the need for excessive heating and cooling. The energy efficiency can contribute to lower operational costs and a reduced carbon footprint over the life of the data center.

Precast concrete also supports the use of recycled materials, hence it enhances its sustainability credentials. When combined with energy-efficient systems and renewable energy sources, data centers built with precast concrete can achieve higher levels of environmental performance. It’s a good idea to integrate this material into construction projects in order to align with green building standards.

Contact Garrett Precast For Quality Concrete Precast Products

Garrett Precast is the precast company you can trust when you’re in need of quality concrete products that are built with durability and versatility in mind. Our concrete solutions cater to diverse needs within the construction industry. For more information about our products, contact us online or give us a call.