Today, Garrett Precast looks into why precast concrete solutions have remained relatively stable in a market where material prices fluctuate wildly. As a trusted precast company, we understand what contributes to this cost stability.

Understanding Precast Concrete Pricing

Precast concrete pricing isn’t just about the raw materials—it’s a combination of production efficiency, transportation, and installation factors. Unlike traditional concrete, which requires extensive on-site labor and curing time, precast components are manufactured in controlled environments, reducing unpredictable expenses. Costs are influenced by material availability, design complexity, and factory overhead. However, the streamlined production process helps maintain consistent pricing, making it a more predictable option for builders.

Market Volatility and Construction Material Costs

The construction industry is no stranger to price swings. From fluctuating cement costs to unpredictable fuel prices, market volatility can wreak havoc on project budgets. Supply chain disruptions, geopolitical issues, and inflation further complicate the situation, making it difficult to estimate expenses accurately. Fortunately, precast concrete helps mitigate these risks. Since it’s manufactured off-site and often purchased in bulk, it shields projects from sudden spikes in material costs. This level of cost predictability is a major advantage in an unpredictable market.

Why Precast Concrete Offers Cost Stability

In an industry where cost overruns are common, precast concrete provides a sense of financial stability. Its production takes place in a controlled setting that minimizes labor-intensive processes and reduces waste. This efficiency results in more predictable costs. In addition, because precast elements are designed for durability, long-term maintenance expenses are much lower. Developers and contractors who prioritize budget certainty often turn to precast solutions, knowing they offer a balanced combination of upfront affordability and long-term savings.

The Role of Bulk Production in Controlling Precast Concrete Costs

Mass production is one of the biggest cost-saving factors in precast concrete. When manufacturers produce large quantities of standardized components, they reduce per-unit expenses through economies of scale. Bulk purchasing of raw materials also helps stabilize prices, making costs less susceptible to market fluctuations. Also, streamlined production minimizes labor inefficiencies. For large-scale construction projects, this advantage is invaluable, as it ensures precast concrete products are affordable without compromising quality. In a market prone to instability, bulk production provides a buffer against price volatility.

Energy and Labor Costs in Precast vs. Traditional Construction

Precast concrete often presents advantages in energy and labor costs compared to traditional on-site construction. The controlled factory environment allows for optimized production processes. Therefore, it reduces energy consumption and minimizes material waste. Labor costs can also be more predictable, as much of the work is done in a factory setting that is less susceptible to weather delays and other on-site inefficiencies. This streamlined production process further reduces overall labor expenses and associated costs.

Garrett Precast: Providing Reliable Precast Solutions

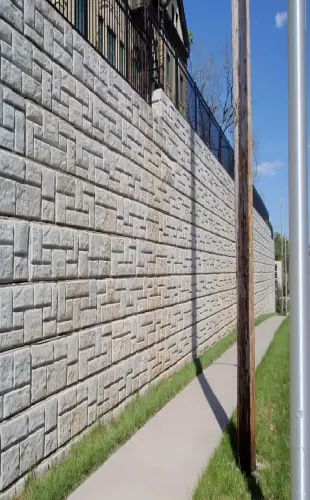

Looking for high-quality precast concrete products? Get in touch with Garrett Precast. We manufacture and supply a wide range of precast concrete products, including concrete septic tanks, seawall products, retaining walls in Anderson, SC, septic tank risers, and more. We have set ourselves apart by delivering high-quality products and staying ahead of the curve when it comes to innovation. Contact us to learn more about our products and let us know what your needs are, and we’ll be glad to provide you with customized solutions.